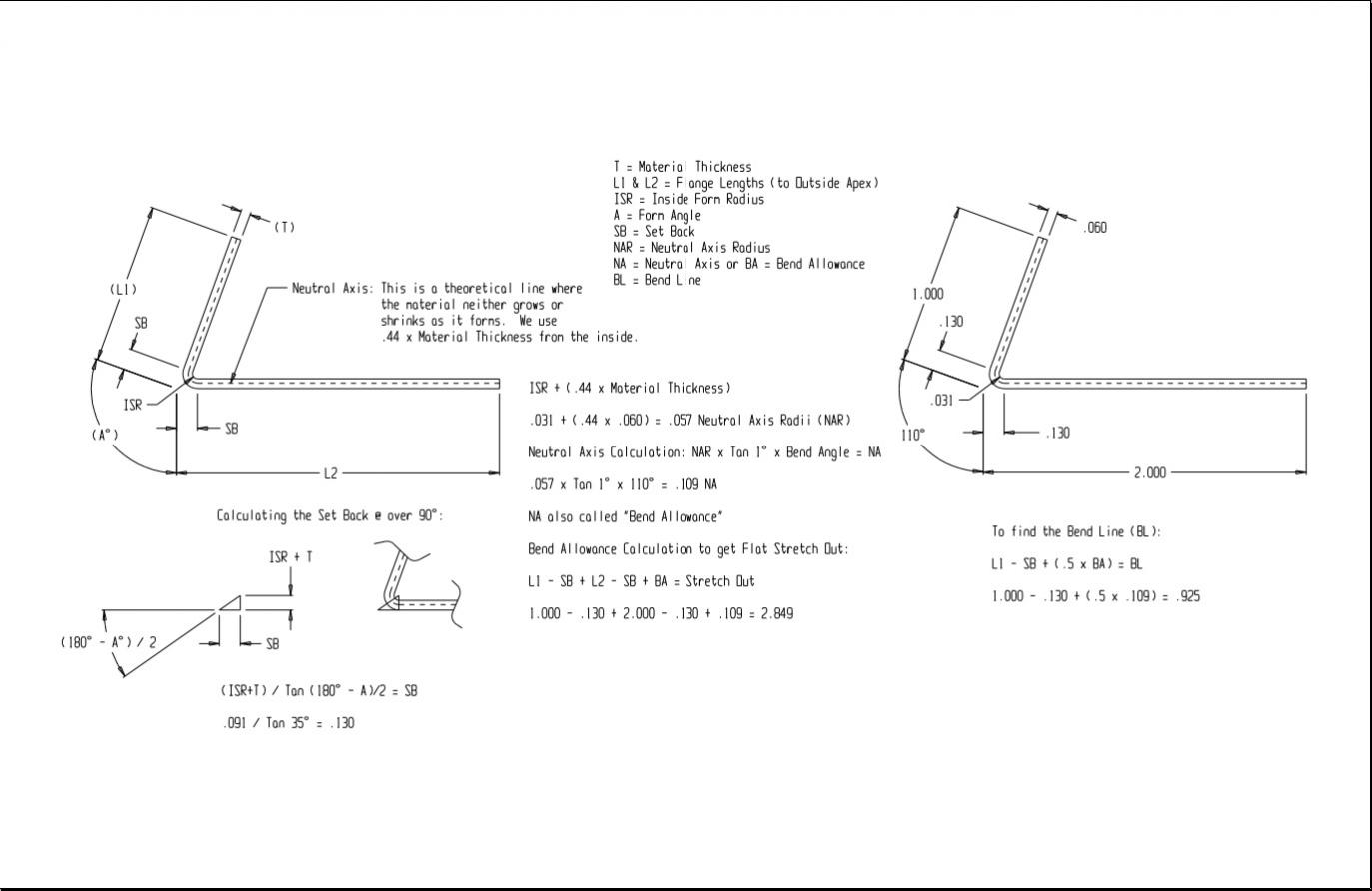

Air bending one of the three types of bending for sheet metal where the outside mold line is not pressed against the die.

Sheet metal development length calculation excel.

Ultimate tensile strength psi.

Sheet metal flat length can be calculated using cad softwares.

Cells on the right will output the desired values.

We are going to review three bending scenarios with three different bending angles.

K factor in sheet metal bending is a constant that is used to calculate sheet metal flat length.

But the most accurate way to find out k factor is reverse engineering of a small but same sheet metal sample piece.

This is used to calculate the back stop location when working off of a flat pattern.

J bown.

Dished head calculation of blank dia.

Sheet metal development calculator is a really simple tool for calculation of development of a sheet metal part.

60 90 and 120 and we will calculate k factor bend allowance and bend deduction for them.

Overview of pressure vessel design to as 1210 ver 3c.

There are standard charts available with sheet metal design handbook for calculating k factor ideally it should be 0 5.

With this free online tool we quickly get the sheet metal bend deduction and therefore the sheet metal blank initial flat length from the finished part measurements.

Therefore using k factor there is no need to calculate sheet metal flat length manually.

Punch edge radius in.

Sheet metal development calculator is a really simple tool for calculation of development of a sheet metal part.

Procedure is as below.

Air bend force chart a chart used to calculate the tonnage required for a bend based on thickness tooling and length.

Transition patterns available flat pattern segments lobsterback bend elbow ellipsoidal dome head tee offset tee square and rectangle to round frustum cone.

For example if the value of k factor for given material thickness and bending machines is known.

3243 minor chord length.

Dish end calculations as per asme section vii div 1.

Die edge radius in.

Consider a sheet with a 20 mm thickness and a length of 300 mm as shown in figure 1.

Sheet metal round fitting fabrication.

3535 major chord length.